NFC Transformer provides both standard and custom designs with following features.

105/130/155 degree insulation systems are available.

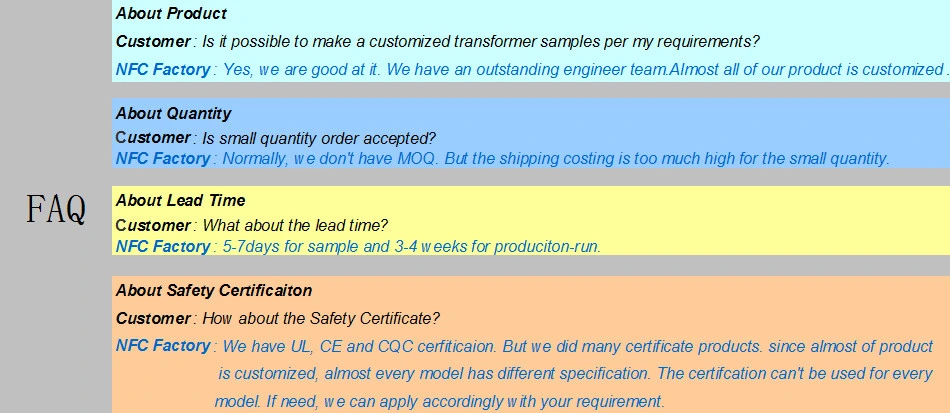

Design to meet UL/CSA/TUV/VDE/CE and other appointed safety agency requirements.

Auto transformer and insulated transformer can be design according to requirements.

100/110/115/120/208/220/230/240/277/380/415V/440V or specified primaries are optional.

Terminations and mounting means can be customized.

Key Specifications

Power Range: 50VA to 3000VA

Phase: Single

Input/Output: Customized

Insulation: 4kV (Hi-pot)

ROHS and REACH environmental instructions

Can design to meet UL/CSA/TUV/VDE/CE and others

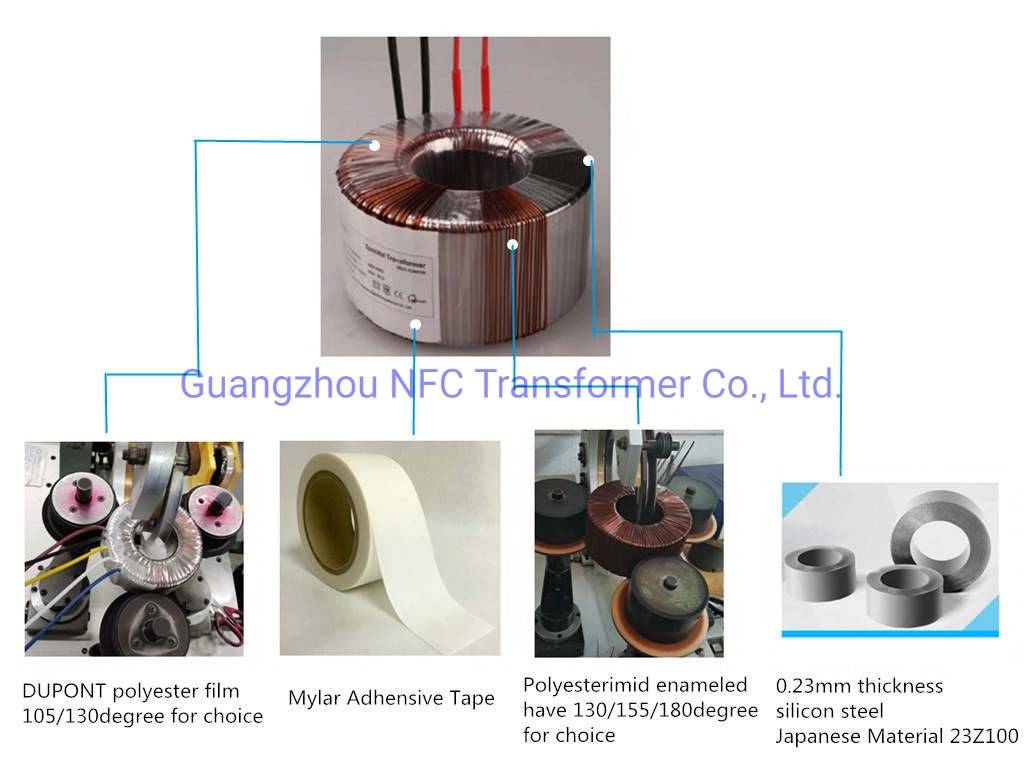

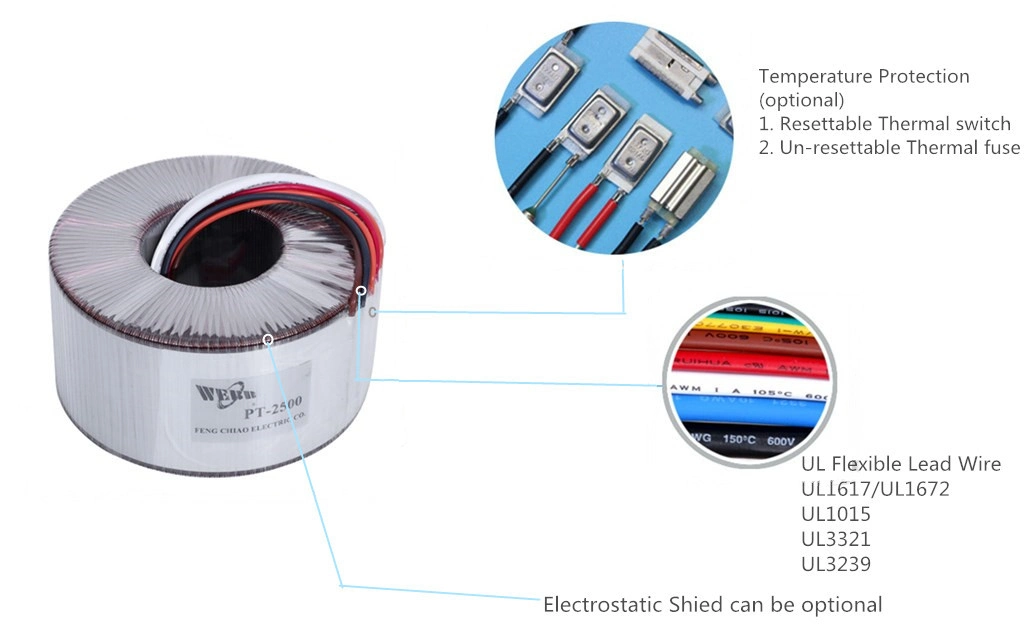

Toroidal Transformer Main Materials (IQC process)

All the material is inspected strictly with ISO9001:2008 quality program.

Core: appearance inspection and core loss test.

Copper wire: pinhole test and coat of adhesion test

Toroidal Transformer Process

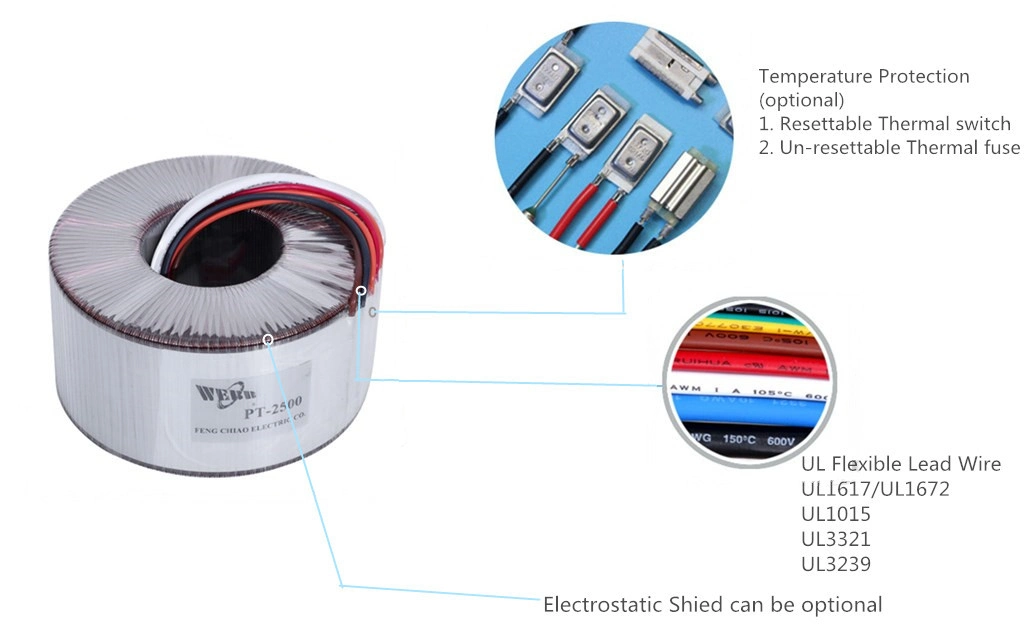

1. Core is from 0.23mm thick silicon steel Japanese material 23Z100.

2. Core is protected from 4 layer polyester films with 0.075mm thick (50% overlap 2 layers). The brand of polyester films is DUPONT.

3. Primary winding wire is polyesterimid enameled, have 130/155/180degress for choice.

4. Primary lead wire from type UL1617 double insulation for 600V voltage and 105 degree.

5. Insulation between primary and secondary is overlap 67% 2 layers , 4 layers polyester films or 50% 4 layers, 8 layers polyester films. It is subjects to different safety agency requirements. The brand of polyester films is DUPONT.

6. Secondary winding wire is polyesterimid enameled, have 130/155/180degress for choice.

7. Secondary lead wire from type UL1015 for 600V voltage and 105 degree.

8. Outer insulation is overlap 50% 1 layers, 2 layers polyester films. The brand of polyester films is DUPONT.

Transformer Testing Items

1. Exciting current & core loss: 100% test

2. DC Resistance: 100% test

3. Layer insulation: 100% test

4. Loading test: 100% test

5. Hi-pot test: 100% test, but the time is only approx 10seconds for the production-run.

6. Aging test: Spot check, 10% of product quantity

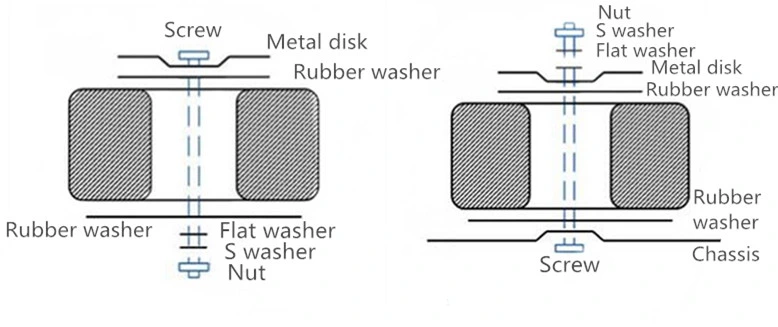

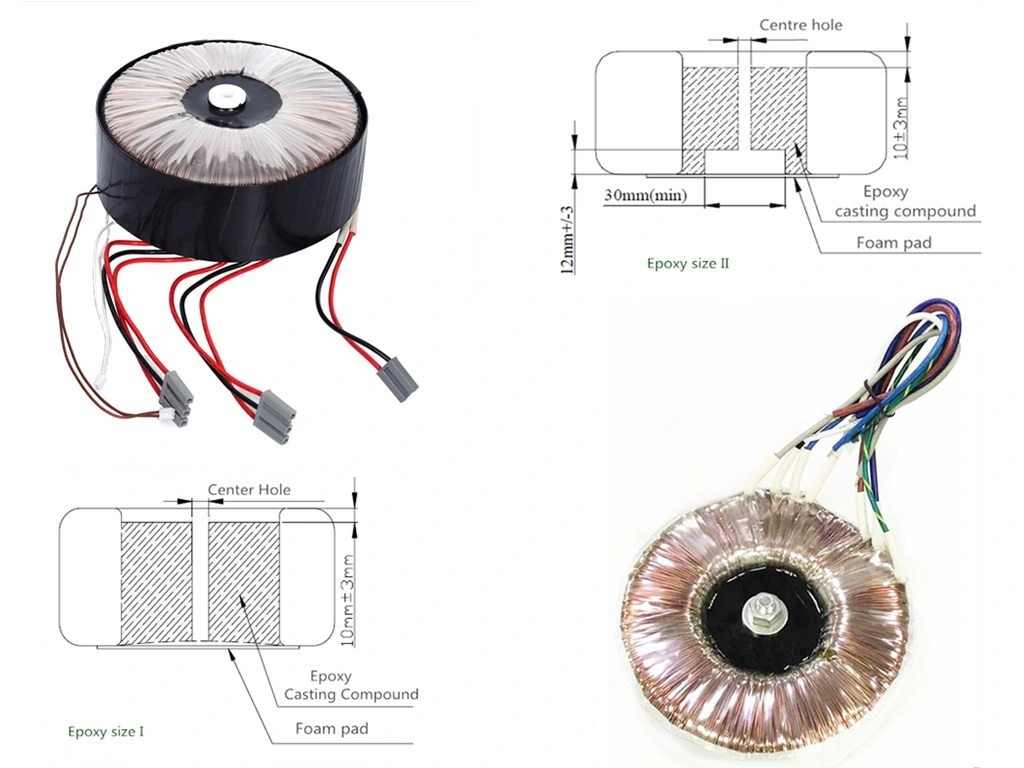

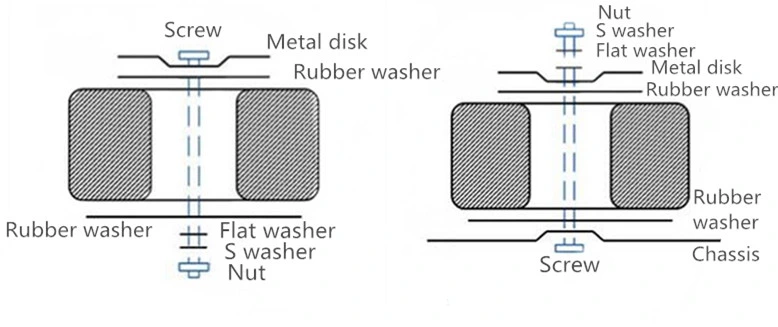

Assembly means, two mounting way for choice.

1. Rubber mounting

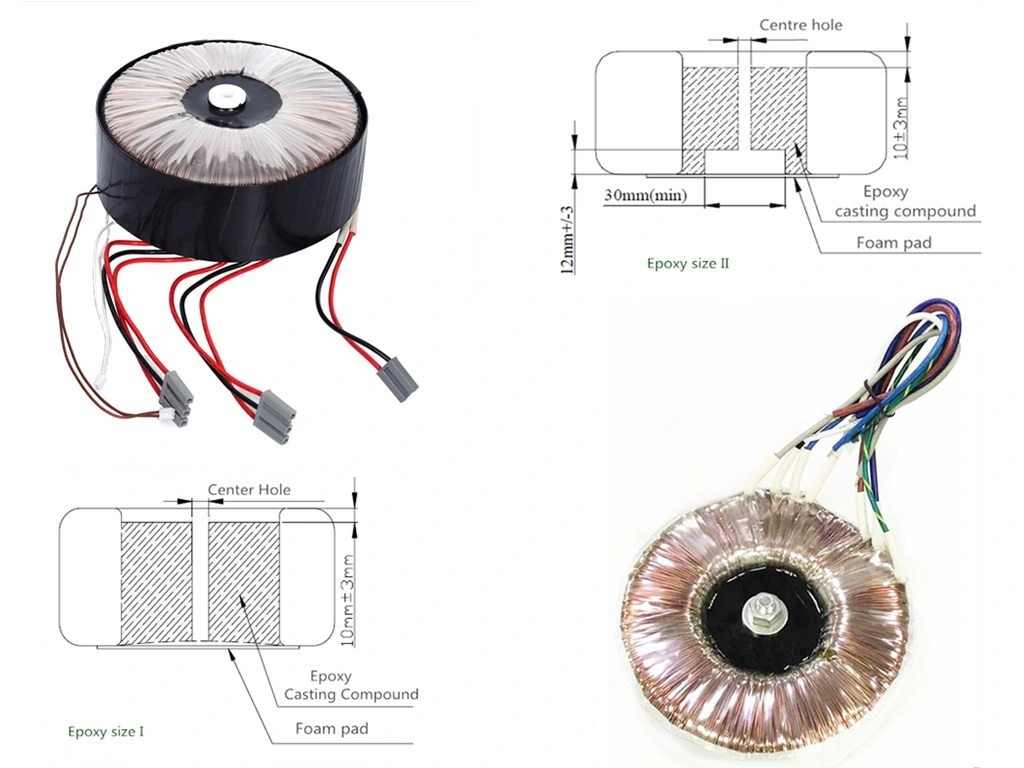

2. Epoxy in the centre

Transformer applications

Widely use in Medical, Industrial Equipment, Auto Control System, Railway, fire system, Amplifier, Test equipment, UPS, Sola, Lighting, Communications and so on.

Certifications

Exhibition

Our advantages

We have professional design teams. And we have been supplying solutions for designing, sampling, engineering, producing custom-made transformers in difference using application for more than 27years. We understand how to optimize the product to cut down the cost according to different applications. We have factory both in Guangzhou, China and Taiwan. You can choose to Made in China or Made in Taiwan.

105/130/155 degree insulation systems are available.

Design to meet UL/CSA/TUV/VDE/CE and other appointed safety agency requirements.

Auto transformer and insulated transformer can be design according to requirements.

100/110/115/120/208/220/230/240/277/380/415V/440V or specified primaries are optional.

Terminations and mounting means can be customized.

Key Specifications

Power Range: 50VA to 3000VA

Phase: Single

Input/Output: Customized

Insulation: 4kV (Hi-pot)

ROHS and REACH environmental instructions

Can design to meet UL/CSA/TUV/VDE/CE and others

| Power | Regulation | Temp. Rise | Efficiency | Product Size OD×ID×H (mm) |

| 50VA | 12.5% | 45°C | 88.0% | 89×44×36 |

| 75VA | 12.5% | 55°C | 88.0% | 89×43×42 |

| 100VA | 11.0% | 55°C | 89.0% | 100×45×38 |

| 150VA | 9.0% | 55°C | 90.5% | 106×47×43 |

| 200VA | 8.0% | 55°C | 92.5% | 114×48×50 |

| 250VA | 7.6% | 55°C | 93.0% | 116×46×50 |

| 300VA | 7.0% | 55°C | 93.3% | 122×48×56 |

| 350VA | 6.5% | 60°C | 93.5% | 123×46×57 |

| 400VA | 5.8% | 60°C | 93.7% | 131×48×57 |

| 450VA | 5.6% | 60°C | 94.0% | 124×45×58 |

| 500VA | 5.5% | 60°C | 94.0% | 132×47×63 |

| 550VA | 5.4% | 60°C | 94.2% | 132×46×68 |

| 600VA | 5.2% | 65°C | 94.3% | 142×49×64 |

| 650VA | 5.0% | 65°C | 94.5% | 142×48×69 |

| 700VA | 4.8% | 65°C | 94.5% | 142×48×72 |

| 750VA | 4.7% | 65°C | 94.5% | 142×48×75 |

| 800VA | 4.7% | 65°C | 94.6% | 152×52×70 |

| 850VA | 4.6% | 65°C | 94.6% | 152×52×72 |

| 900VA | 4.6% | 65°C | 94.8% | 152×52×75 |

| 950VA | 4.5% | 65°C | 94.8% | 162×54×71 |

| 1000VA | 4.5% | 65°C | 95.0% | 162×53×72 |

| 1100VA | 4.4% | 70°C | 95.0% | 162×49×75 |

| 1200VA | 4.3% | 70°C | 95.2% | 163×49×78 |

| 1300VA | 4.2% | 70°C | 95.3% | 172×52×76 |

| 1400VA | 4.1% | 70°C | 95.4% | 172×51×79 |

| 1500VA | 4.0% | 70°C | 95.5% | 172×51×84 |

| 1600VA | 4.0% | 75°C | 95.5% | 180×55×88 |

| 1700VA | 4.0% | 75°C | 95.5% | 180×55×88 |

| 1800VA | 3.9% | 75°C | 95.5% | 180×54×93 |

| 1900VA | 3.9% | 75°C | 95.5% | 181×53×94 |

| 2000VA | 3.8% | 75°C | 95.5% | 181×53×100 |

| 2150VA | 3.7% | 75°C | 95.7% | 195×58×88 |

| 2300VA | 3.5% | 75°C | 96.0% | 195×58×93 |

| 2450VA | 3.5% | 75°C | 96.2% | 196×57×94 |

| 2600VA | 3.4% | 75°C | 96.3% | 196×57×99 |

| 2750VA | 3.4% | 75°C | 96.3% | 196×57×105 |

| 2900VA | 3.3% | 75°C | 96.4% | 206×68×105 |

| 3000VA | 3.2% | 75°C | 96.4% | 206×68×105 |

Toroidal Transformer Main Materials (IQC process)

All the material is inspected strictly with ISO9001:2008 quality program.

Core: appearance inspection and core loss test.

Copper wire: pinhole test and coat of adhesion test

Toroidal Transformer Process

1. Core is from 0.23mm thick silicon steel Japanese material 23Z100.

2. Core is protected from 4 layer polyester films with 0.075mm thick (50% overlap 2 layers). The brand of polyester films is DUPONT.

3. Primary winding wire is polyesterimid enameled, have 130/155/180degress for choice.

4. Primary lead wire from type UL1617 double insulation for 600V voltage and 105 degree.

5. Insulation between primary and secondary is overlap 67% 2 layers , 4 layers polyester films or 50% 4 layers, 8 layers polyester films. It is subjects to different safety agency requirements. The brand of polyester films is DUPONT.

6. Secondary winding wire is polyesterimid enameled, have 130/155/180degress for choice.

7. Secondary lead wire from type UL1015 for 600V voltage and 105 degree.

8. Outer insulation is overlap 50% 1 layers, 2 layers polyester films. The brand of polyester films is DUPONT.

Transformer Testing Items

1. Exciting current & core loss: 100% test

2. DC Resistance: 100% test

3. Layer insulation: 100% test

4. Loading test: 100% test

5. Hi-pot test: 100% test, but the time is only approx 10seconds for the production-run.

6. Aging test: Spot check, 10% of product quantity

Assembly means, two mounting way for choice.

1. Rubber mounting

2. Epoxy in the centre

Transformer applications

Widely use in Medical, Industrial Equipment, Auto Control System, Railway, fire system, Amplifier, Test equipment, UPS, Sola, Lighting, Communications and so on.

Certifications

Exhibition

Our advantages

We have professional design teams. And we have been supplying solutions for designing, sampling, engineering, producing custom-made transformers in difference using application for more than 27years. We understand how to optimize the product to cut down the cost according to different applications. We have factory both in Guangzhou, China and Taiwan. You can choose to Made in China or Made in Taiwan.