Transformer oil dehydration plant oil filtering machine for transformer

Application

- This machine is applied to purify the unqualified transformer oil, mutual inductor oil,

Main Features

- With high vacuum pump. Vacuum degree can up to -0.098 Mpa.

- 3D flashing by vacuum, it can eliminate the liquid water quickly. And Use UK micro technology to remove the trace water and other dissolved water. The final oil water content can be <= 5ppm, gas content can be < 0.1%

- With Z type heater design, and the face of the heater is smooth, it can heating uniformity, avoid extra gas

- Three stages filters, it combines double FH trapezoidal network and high polymer material absorption technology, the particle's precision can up to 5μ

- We use fluoric cushion not normal cushion, and double welding of the machine, with great sealing performance, can avoid extra gas and have longer life

- With automatically oil level control device

Working principle

- When we turn on the machine, start to purify the oil, the oil will come into the primary filter

- After that oil will flow into the heater, then into the vacuum tank to dehydration and

- Then the oil flow through the second filter, normally 50μ

- Then the oil will flow into the fine filter, normally 5μ

- Oil comes out or keep the loop working

Maintenance

- After a certain period of running, the machine should be checked to see whether:

- The electrical control system is safe and reliable;

- The temperature controller is sensitive, reliable and accurate;

- Oil seals of the pump shaft are broken with leakage;

- There is any blockage with the running system and any abnormal noise with pumps or related motors;

- There is any air or oil leakage with the oil running system and at sealing joints.

- After each 3000 hours' running, grease shall be replenished to prevent motors from being burnt.

- Special vacuum pump oil or lubricating oil N46 should be used fro the vacuum pump and oil replaced or replenished if necessary at any time.

- If the machine will not be used over 1 month, Place the machine in a dry environment with the panel door and all valves closed, and the machine proper protected by a covering.

Parameters Unit ZY-10 ZY-20

ZYA-20ZY-30

ZYA-30ZY-50

ZYA-50ZY-100

ZYA-100ZY-150

ZYA-150ZY-200

ZYA-200ZY-300

ZYA-300Flow rate L/min 10 20 30 50 100 150 200 300 Working vacuum MPa -0.06 ~ -0.095 Working pressure MPa 0.4 0.4 ≤0.4 0.5 0.5 0.5 0.5 0.5 Breakdown voltage KV ≥55 ≥55 ≥55 ≥60 ≥60 ≥60 ≥60 ≥65 Moisture PPM ≤5 Gas content % ≤0.1 Impurity content μm ≤5 Temperature range ºC 10 ~ 100 Power supply 50HZ380V(being regulated according to customer's option) Working noise dB(A) 61 63 70 70 75 70 70 70 Heating power KW 11 13 15 30 48 52.5 57.5 60 Total power KW 12.5 14.5 16.5 33.5 51.5 57.5 65.5 68 Inlet/outlet caliber mm φ25 φ25 φ25 φ32 φ42 φ50 φ50 φ60 Weight Kg 150 200 260 300 400 450 550 600 Size L mm 1050 1050 1100 1200 1450 1600 1800 1900 W mm 750 750 800 950 950 1100 1200 1200 H mm 1350 1350 1400 1500 1650 1800 1900 1900

Pre-sale Service

According to customer's demands, we recommend the most suitable machine with high cost effective.

Free on-site installation, debugging and technical training (offered by strictly trained technology application engineers)

Offer OEM service.

After-sale Service

We offer the door-to-door after sales service for installation and debugging.

The warranty period is 24 months from commissioning acceptance date on.

We build instrument service profile for our clients to record the product service and maintenance conditions.

Company Information

Packing and Delivery

Safe and Timely Transportation

Standard export wooden case with high quality cushioning material ensures that the customers get the item in good condition.

Carefully check every packing detail before delivery to avoid any troubles during the transportation.

Appointed logistics company could be used according to customers demands.

Do our best to make sure customers can get the goods in time.

According to customer's demands, we recommend the most suitable machine with high cost effective.

Free on-site installation, debugging and technical training (offered by strictly trained technology application engineers)

Offer OEM service.

After-sale Service

We offer the door-to-door after sales service for installation and debugging.

The warranty period is 24 months from commissioning acceptance date on.

We build instrument service profile for our clients to record the product service and maintenance conditions.

Company Information

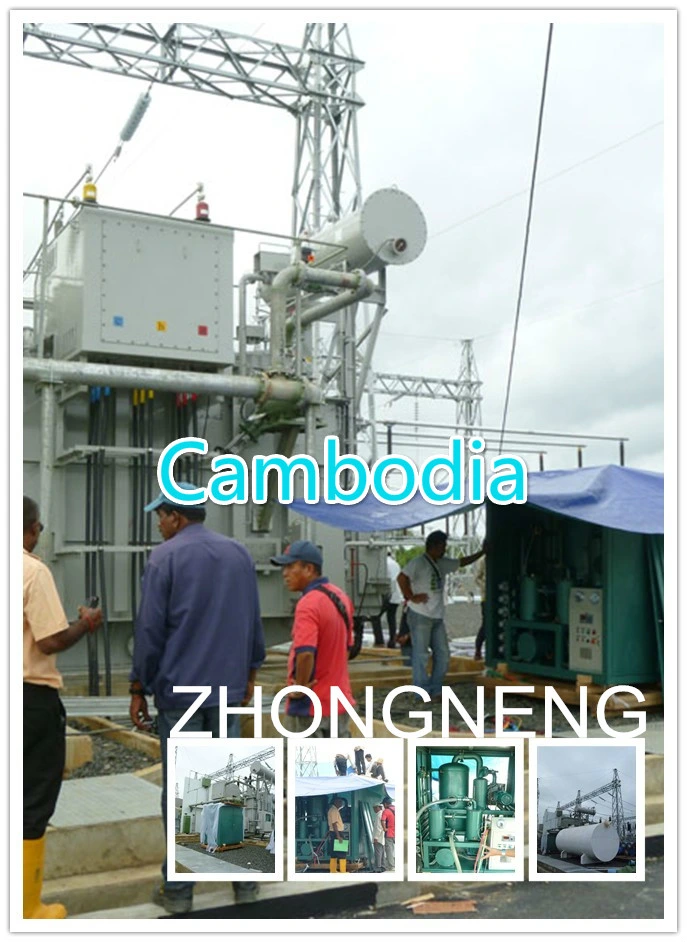

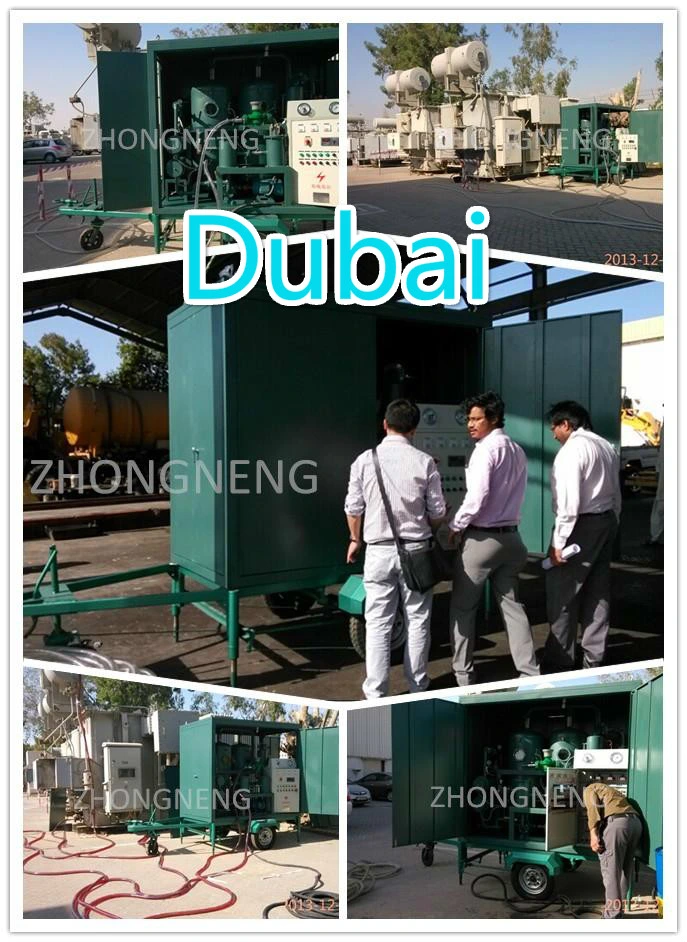

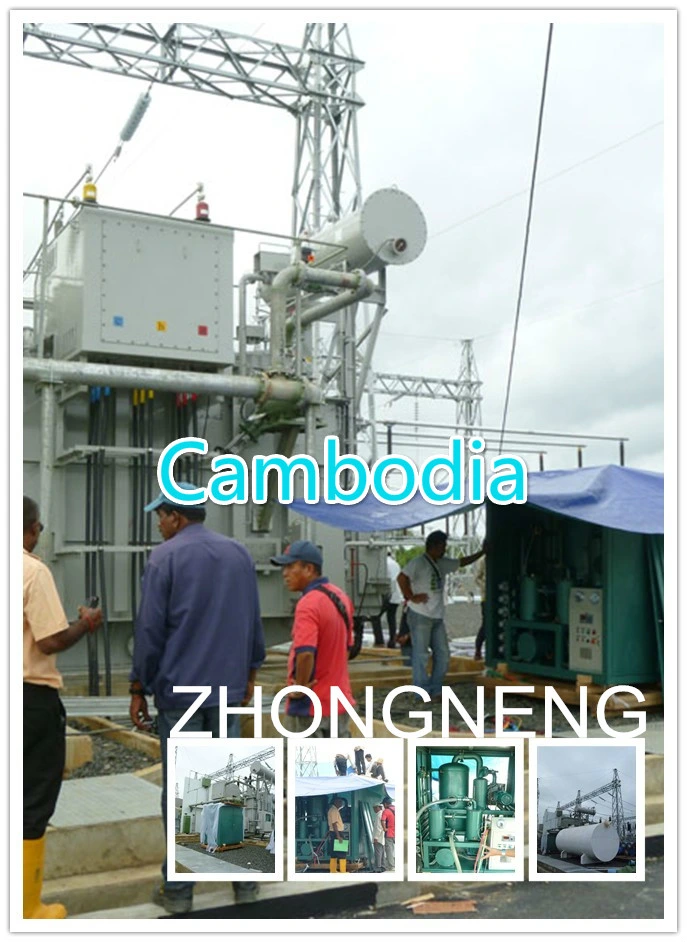

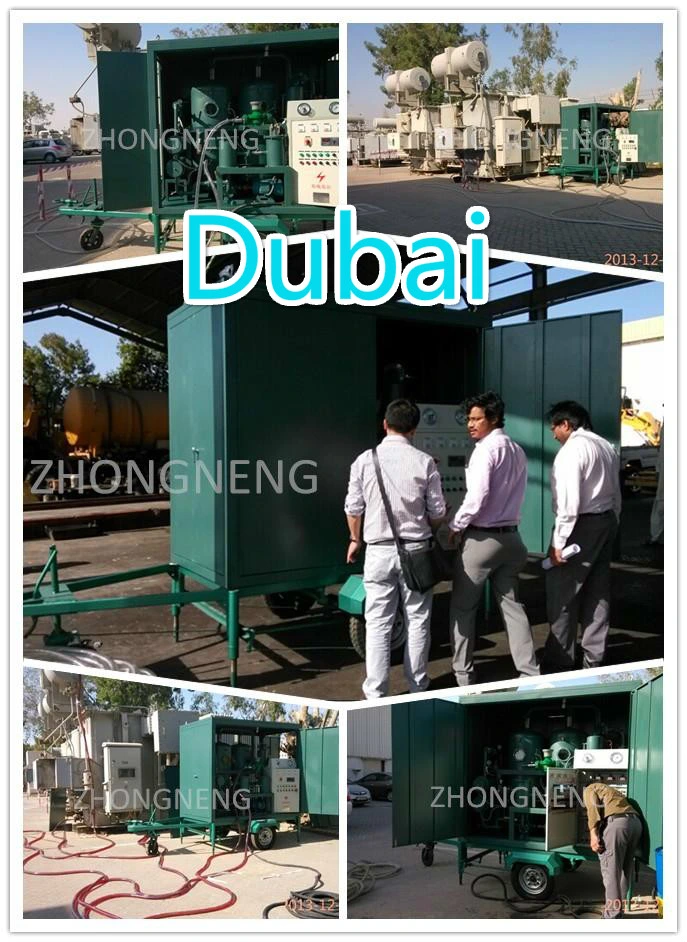

- We are the professional manufacturer and exporter of oil purifier in China

- We are in this field since 2004

- We are the 13-year golden supplier on Alibaba

- We offer our customers professional products at competitive price

- We offer our customer reliable lifetime after-sales service

Packing and Delivery

Safe and Timely Transportation

Standard export wooden case with high quality cushioning material ensures that the customers get the item in good condition.

Carefully check every packing detail before delivery to avoid any troubles during the transportation.

Appointed logistics company could be used according to customers demands.

Do our best to make sure customers can get the goods in time.