A padmount or pad-mounted transformer substation is a ground mounted electric power distribution transformer in a locked steel cabinet mounted on a concrete pad. Since all energized connection points are securely enclosed in a grounded metal housing, a padmount transformer can be installed in places that do not have room for a fenced enclosure. Padmount transformers are used with underground electric power distribution lines at service drops, to step down the primary voltage on the line to the lower secondary voltage supplied to utility customers. A single transformer may serve one large building, or many homes.

Pad-mounted transformers are made in power ratings from around 75 to around 5000 kVA and often include built-in fuses and switches. Primary power cables may be connected with elbow connectors, which can be operated when energized using a hot stick and allows for flexibility in repair and maintenance. Our company can custom made as customers'requirements.

HFY pad-mount transformers are available in various electrical and mechanical configurations. Pad-mount transformers operate on medium-voltage distribution systems, up to about 40.5 kV. The low-voltage winding matches the customer requirement and may be single-phase or three-phase.

Pad-mount transformers are (nearly always) oil-filled units and so must be mounted outdoors only. The core and coils are enclosed in a steel oil-filled tank, with terminals for the transformer accessible in an adjacent lockable wiring cabinet.

The wiring cabinet has high and low voltage wiring compartments. High and low voltage underground cables from below enter the terminal compartments directly. The top of the tank has a cover secured with carriage bolt-nut assemblies. The wiring cabinet has sidewalls on two ends with doors that open sideways to expose the high and low voltage wiring compartments.

Pad-mount transformers have self protecting fuses consisting of a bayonet mount fuse placed in a high voltage compartment, with a back-up high energy current limiting fuse in series to protect against secondary faults and transformer overload. The bayonet mount fuse protects against secondary faults and transformer overload and is a field replaceable device. The backup current limiting fuse operates only during transformer failure, therefore it is not field replaceable. These transformers also serve the conventional low voltage fusing requirements.

The use of polymeric cable and load break elbows enable switching and isolation to be carried out in the HV chamber in what is known as a "dead front" environment, i.e. all terminations are fully screened and watertight.

Single- and three-phase pad-mounted transformers are used in underground industrial and residential power distributionsystems, where there is a need for safe, reliable and aesthetically appealing transformer design. Their enclosed construction allows the installation of pad-mount transformers in public areas without the need of protective fencing. In residential areas, pad-mount transformers are usually located on street easements and supply multiple households.

Three-phase pad-mounted transformers range in sizes from 75 kVA up to 5000 kVA with voltages ranging from 2,400 up to 34,500 delta or wye. Low-voltage pad-mounted range in size from 208y/120 through 24,940y/14,000.

While most traditional pad-mount transformer are fixed on a concrete 'pad', today small single-phase designs are also available with the transformer already mounted on a 'polypad' base so that they can be mounted on hard ground, connected, and switched on.

The MT-PMO-1P-14400.24960-25KVA-120.240-N3R-CU 14400/24960V 1 Phase Energy Efficient Pad Mount Oil Cooled Transformer from Larson Electronics is powerful, reliable and designed with the environment in mind. Suitable for both indoor and outdoor applications, the MT-PMO-1P-14400.24960-25KVA-120.240-N3R-CU provides increased reliablity and protection against critical equipment failures. The lower operating costs, lower heat emissions and lower cost of ownership make this transformer ideal for a wide range of applications and businesses. *PLEASE NOTE: ANY FREE SHIPPING OFFERS DO NOT APPLY TO POWER DISTRIBUTION PANELS, TRANSFORMERS, OR SUBSTATIONS* Transformer Features: With a transformer rating of 25kVA, the MT-PMO-1P-14400.24960-25KVA-120.240-N3R-CU transformer is a single phase unit with a primary voltage of 14400/24960V. It also provides a secondary voltage of 120/240V. Featuring robust construction, this unit`s cores are manufactured with non-aging, cold-rolled silicon steel laminations using state of the art technology. This unit boasts a low cost of ownership and is highly energy efficient. Lower heat emissions mean less cooling is needed as well. The Standard NEMA Type 3R enclosure makes the unit suitable for both indoor and outdoor applications and it can be pad mounted. The unit also features FR3 mineral oil cooling, a 65°C temperature rise and is rated IP24. The MT-PMO-1P-14400.24960-25KVA-120.240-N3R-CU is designed so that no excess oil heating occurs from unbalanced loads or phase loss on the primary side. Benefits: The MT-PMO-1P-14400.24960-25KVA-120.240-N3R-CU pad mount transformer offers many benefits to the consumer. Precision cut copper transformer winding material help to improve performance. The close tolerances used during manufacturing also eliminates burrs which hinder performance. Each core is specially coated to prevent the ingress of moisture and are electrically balanced to minimize axial forces during short circuit situations. This transformer provides owners with significant energy savings as well as offering environmental benefits. Higher efficiency not only extends the life of the transformer, but also turn into cost savings for owners in the form of lower energy bills and decreased cost of ownership. |

Our Workshop

Company Introduction

Qingdao Hengfengyou Electrical Engineering Co., Ltd. (hereinafter referred to as Hengfengyou) is a large-scale enterprise group with electricity transmission and distribution as its main business,which integrates scientific research, development, manufacturing and trade. After 30 years rapid economy development in China, Hengfengyou now is a leading R & D, manufacturing and service base for MV , HV and ultra-HV power distribution equipment in China. At present,we have 50 senior technicians and more than 300 employees, with a complete sales and service system. Our products sell well at home and abroad, and our annual output value adds up to $100 million. .

At present, Hengfengyou has 6 wholly-owned and holding subsidiaries, which are respectively engaged in R & D, manufacturing and service of transformers, switchgear, package/unit substation, pole-mounted high-voltage vacuum circuit breakers, new energy, and electrical engineering. For a long time, the company has maintained close technical exchanges and cooperation with domestic and foreign universities, scientific research institutes and electric power enterprises. Hengfengyou independently designed and developed SCB series dry-type transformer and SC series oil immersed transformer. Our product performs with high operation efficiency, and obvious energy conservation. The overall performance index reaches the world's advanced level. The company also maintains long-term strategic partnership with Schneider, ABB, Simens, Chint and other electric suppliers. We absorbed foreign advanced experience in electrical equipment production and independently designed and developed a series of substation equipment, which realized the automation and intelligence of the substation, and of which the performance has been highly recognized by the user at home and abroad. In the following five years, the company plans to build an intelligent workshop with an annual output of 100000 transformers.Then,the intelligent robot will replace 80% of the existing labor force, which will greatly improve the production efficiency, lower production cost, and produce more energy-saving, environmentally friendly, more safe and reliable the product for the users!

Under China's one belt, one road policy and as an outstanding one of China manufacturing enterprises of power transmission and distribution equipment, Hengfengyou has provided reliable electrical products and services for more than 50 countries and regions in the world. A good reputation of the brand name "HFY" was established in the global market, and won wide recognition and trust from customers. In the new era, the company will adhere to the service concept of "global intelligent electric service provider, make life better", and adhere to the enterprise tenet of "integrity, innovation, customer achievement". We take "high quality products, wholehearted service" as the team spirit, and provide more excellent products and services for customers at home and abroad. Hengfengyou sincerely hope to establish with clients at home and abroad long-term win-win cooperation facing the future!

HFY Certificate

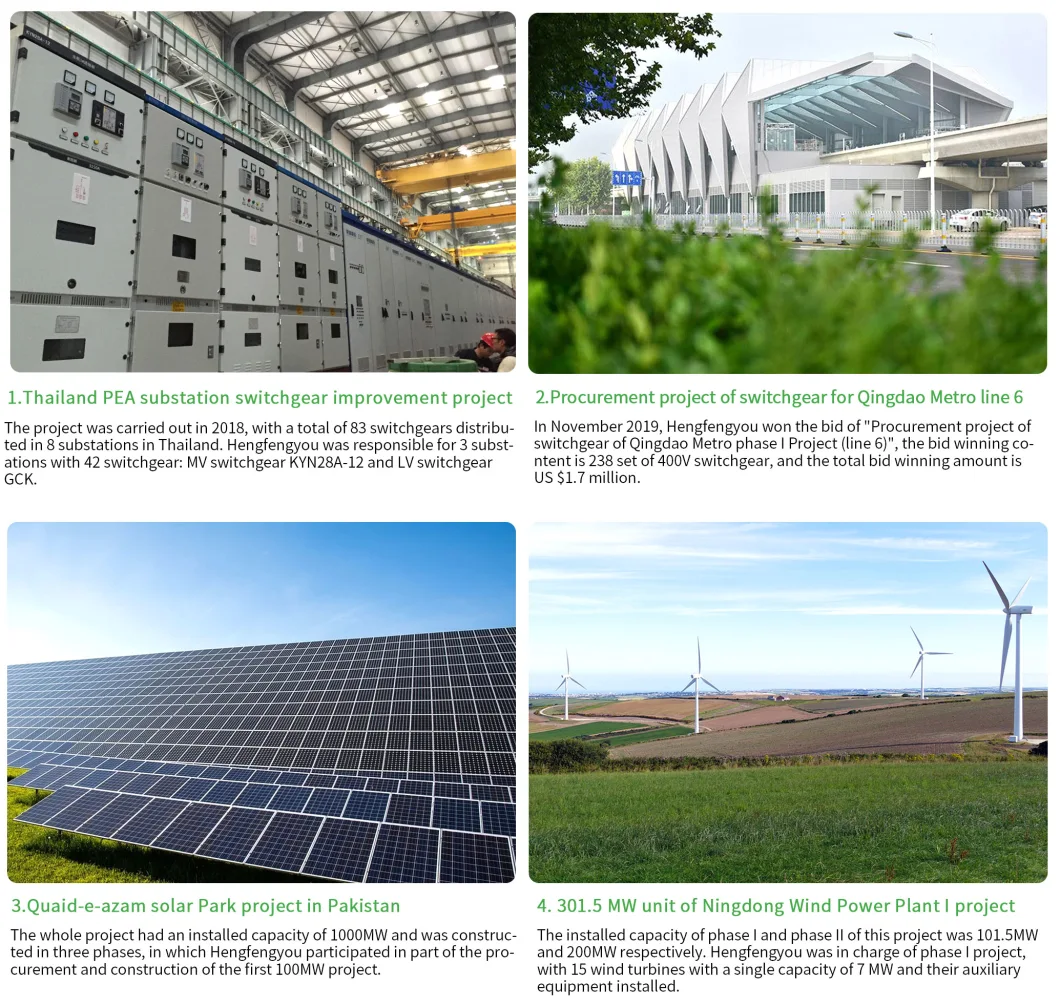

The finished project

Our Services

1.Pre sale service

a. make technical solution

b. send quotation, technical data sheet and drawing

c. prepare power transmission plan, testing plan and shipment plan

2. In sale service

a. supervise the manufacturing schedule totally in accordance with the plan

b. send photos to customer during every manufacturing process(hold point)

c. inform the customer one week before testing.

d. quick response within 12 hours any time.

3. After sale service

a.All parts are under Two Years Warranty with defects from manufacturer. All spare parts and component can be offered for free from the original manufacturer or HFY.

b. Training

We will provide free training to your technician free of charge at our factory site in Qingdao, China. The total training period would be 2 working days. All travel and related expensed would be at the purchaser's expense.

c. Technical Documents:

Original operation and service manuals, the service manual is completed with wiring diagram, block diagram and trouble shooting information.

d. Installation

Usually, clients can do the installation and operation by themselves when following the detailed English user manual. If clients want our technician do this work, please read the following terms:

The initial installation is not included with the professional HFY team member. All installation with the Hengfengyou team must be scheduled at least 4 weeks in advance before actual trip taken. All necessary connectivity must be ready prior the service being scheduled.

While Hengfengyou team member arrives at the site for a complete and final installation, two days training course will be provide to the customer for operation and maintenance procedure. The initial installation is provided within 5 working days excluding travel days. The actual installation days may vary, based on different machine mode. Each day of working hour consist at 8 working hours. Any additional day will be charge according to our service fee listed below.

When initial installation is being called for the Hengfengyou team required, the surcharge will be made in advance by the purchase at US$100/person/day plus all travel expenses. Travel expenses; local and destination transportation charges (air, train, ferry, bus, taxi or any means of transportation required to arrive to/from destination); accommodation (minimum of 3 star hotel facility) and 3 daily meals

Our Team

FAQ

Q1: Is OEM/ODM available?

A1: Yes, it is! Our products can be Customized. We have design and engineer teams,we can customize products according to customers' drawing or requirements.

Q2: What's your MOQ?

A2: One Set.

Q3: How is the delivery time?

A3: It depends your order quantity and it normally takes about 15-20 days.

Q4: How do you control the quality?

A4: We have QC team comply with TQM to ensure the quality. Each step is in compliance to the standards. At the same time, we will take photos and shoot video for you if you need.Every product will be fully assembled and carefully tested before packing and shipping.

Q5: How long is the warranty?

A5: Within one year from the sale date, if there are any accessory problems, you just provide the photos of damaged accessory, then we will provide free accessory. According to the number of products, we will provide easily damaged accessories for free. We also can provide technical support if you need.